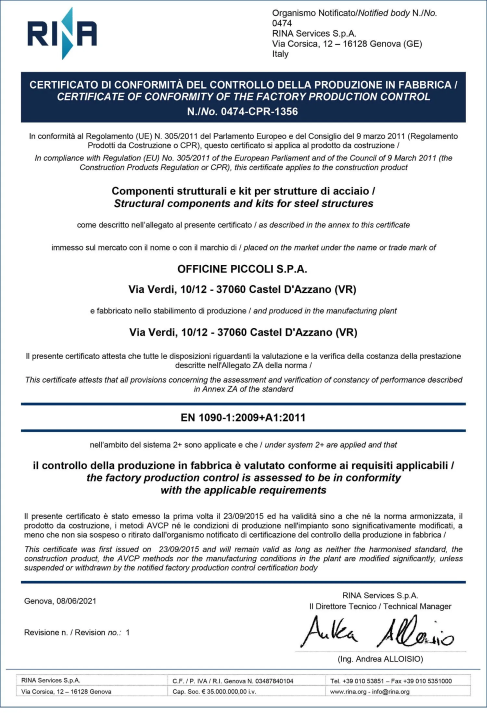

Certified Quality Management System.

Fiber Laser MICROSTEP 8000 W

Working range 14.000mm x 3.000mm

with robotic head for Bevel cutting

Ink Marking

Fiber Laser EAGLE 6000 W

Working range 4.000 x 2.000mm

Automatic metal sheets loading and unloading process with 105 drawers

24 h Production

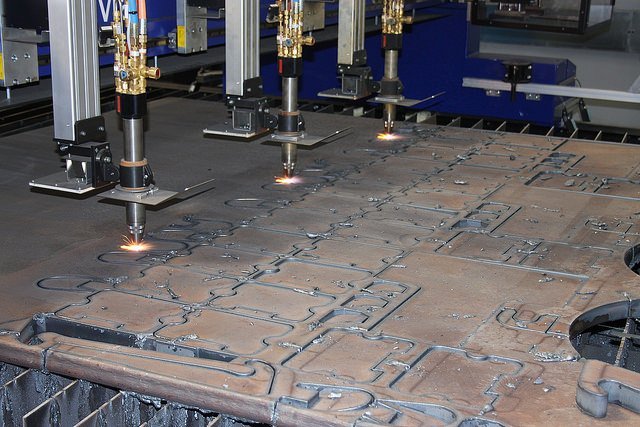

Plasma cutting

MESSER with robotic head for Bevel cutting + straight head, run by 2 HPR 400 A generators with a working range of 25,000 x 3,000 and max thickness up to 50 mm

Oxy-fuel cutting

MESSER with ISO 40 (d 32m) drilling centre. Machining range 18,000 x 3,000 with a thickness of up to 250 mm

Bending

BEYELER 12.000 mm x 1.500 T

LVD 4.000 mm x 320 T

BEYELER 4.000 mm x 225 T

LVD 15000 mm x 3000 T